The Infrastructure Investment & Jobs Act that was recently passed by Congress includes spending for ports, railyards, roads and airports throughout the United States. Additionally, large sums of money are earmarked for broadband, and other forms of information technology (largely aimed at schools). Combining these two areas, to allocate resources for information technology aimed at the supply chain is something that Congress, industry and consumers should demand. Data and analytics are ultimately the keys to speeding up the supply chain on both a short term and a long term basis.

When Time is Money, Information Eliminates Wasteful Idle Time

The freight transportation industry generates revenue by hauling goods from origin to destination. Transportation providers are paid to move goods based on a combination of time, distance and weight. Once ocean freight arrives at the port and transitions to the road, carriers pay their drivers under a similar arrangement. Many truck drivers are paid on a per-mile basis, while other modes pay on a per-trip, per hour, or tonnage basis - but only when the vehicle/vessel is in transit.

When freight is stalled at chokepoints (like it currently is at seaports) then shipping lines, railroads and trucking companies aren’t making money for their crews. If workers can’t make money, they often leave the industry to find employment elsewhere. Beyond the financial stress, another reason workers leave the transportation industry is due to the frustration that comes with delays and schedule inconsistencies.

For truck drivers, delays caused by inefficient operations at ports or shippers’ facilities are more frustrating than sitting in traffic. The more time drivers spend idle, waiting for work, the less money they make. This creates an ever-growing cycle of turnover: delays lead to lower pay, which pushes drivers out of the industry, which in turn leads to more delays. Such turnover costs the transportation industry billions and cripples transportation capacity – because transportation providers only get paid when they complete a trip.

The most important variable that determines profitability for transportation companies is asset utilization, or how much money is generated by an asset over a period of time. The faster a ship or a truck completes a trip, the more availability they have for the same vessel/vehicle to take new shipments. Decreasing the time it takes to complete a trip increases the money a carrier makes. When carriers are profitable, they’re able to grow their fleets and hire additional staff.

Information is the Key to Growth

Consider the following: Why did Uber revolutionize the legacy cab market? Perhaps it’s because Uber’s software effectively leveraged data to quickly pair up drivers with riders willing to pay for the trip.

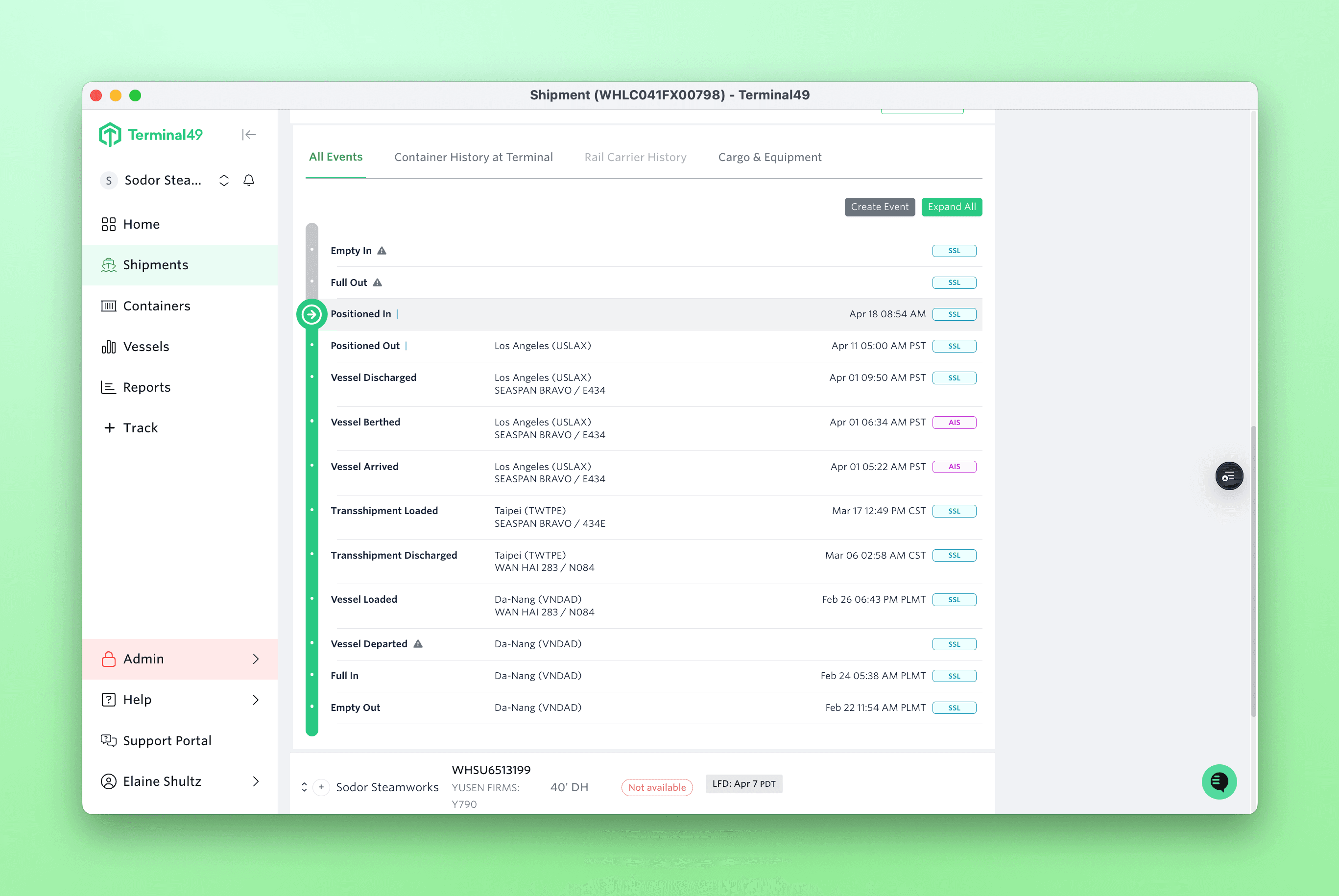

The same enhancements (in terms of speed and efficiency) can be derived throughout the supply chain by implementing technology like Terminal49. Terminal49’s software platform can access more than 97% of all Global Container Traffic – to provide status updates from all major steamship lines and every port & terminal in the USA. Terminal49 also works with numerous trucking companies to extend visibility beyond the water’s edge.

Knowing where cargo is at all times; knowing when containers are offloaded; knowing where containers are staged; knowing when there are delays, and confirming when containers are ready to be picked up provides the visibility carriers & shippers need to efficiently plan driver routes and speed up the supply chain. Data & information are the most important tools carriers have to minimize wasteful idle time, and to bring a sense of planning, organization, and peace-of-mind to their workforce.

The issues in the supply chain are not going to be fixed overnight, and the current infrastructure bill does not provide an immediate answer to all of the industry’s challenges. Long-term planning should prioritize aggregating and leveraging data & analytics across the supply chain. These investments must be made across the board - by government, municipalities, ports, and they should be matched by carriers and other private sector businesses throughout the supply chain. When that happens, global supply chains will become much more efficient. The good news is – the technology exists today, and it’s already being used by many of the world’s most innovative shippers.

Every port, every multi-modal carrier, and every shipper in the United States should utilize an information-aggregation service such as Terminal49. To learn more or to start tracking containers today, visit: https://app.terminal49.com/register.