North American rail and intermodal shipping operations have enjoyed a long and successful history. However, this has not been without its fair share of hiccups. Operational challenges in North American rail and intermodal shipping have continued to rise, and businesses are being impacted. These operational challenges can lead to supply chain disruptions, increased costs, and, sometimes environmental concerns.

Nonetheless, intermodal transport is crucial to logistics operations and helps businesses save on costs, so overcoming these challenges is essential. Running a seamless operation is the difference between success and failure in any shipping process. The same applies to North American rail and intermodal shipping. In this article, we will share useful tips to help you overcome these challenges and give your business a seamless operation.

Operational Challenges in North American Rail and Intermodal Shipping

North American rail and intermodal shipping has had a great history of transporting cargo traversing the continent cheaper and faster than conventional overroad transport. That said, operational challenges do exist within the industry that inhibit efficiencies to navigate North American rail and shipping effectively. Here are some of them:

1. Infrastructural Bottlenecks

The US rail infrastructure, like railroad tracks and bridges, is deteriorating. A sustained lack of financing for infrastructure upkeep results in continued deterioration, which will cause safety concerns and a slowdown in operations. Terminals also tend to get congested, especially at critical junctions and ports. This typically leads to delays in loading and unloading.

2. Scheduling and Coordination in Rail Freight Transportation

North American rail freight transportation faces a shortage of skilled workers and rail operators. The result is a scheduling and coordination problem that plagues the entire operation. Because of these delays, other transportation and supply chain processes can be impacted negatively. Sometimes, it gets so bad that there are supply chain disruptions.

3. Transfer Inefficiencies

Cargo transfer during intermodal transportation can be a tricky process, and because of this, experienced professionals with the right tools for the job are needed. However, a shortage or non-existence of such professionals could slow down the process. The main risk here is that when the transfer from train to truck or vice versa is done poorly, it could damage the cargo.

4. Regulatory and Weather Disruptions

The policies and regulations of rail and intermodal operations are complex and nuanced. Navigating them can be a nightmare, especially concerning fewer greenhouse gas emissions, safety concerns, and weight limits. Harsh weather, such as snow storms and heat waves, can also be detrimental to rail and intermodal shipping operations. They cause delays, which can disrupt the entire process.

Overcoming Operational Challenges in North American Rail and Intermodal Transportation

It is true that these challenges threaten to derail shipping operations and often threaten the business's finances. However, they can be managed, especially with the help of tech solutions like Terminal49. Before we explore how the platform can help, here are some of the traditional ways to overcome them:

1. Proactive Planning

Investing in proactive logistics and supply chain planning is essential to avoid these operational challenges in shipping operations. This entails drawing up contingency and risk mitigation strategies that ensure the supply chain is still in process despite potential delays. One common way to do this is by having buffer stock or inventory on hand. You will also want to leverage technology to get real-time access to high-quality milestone data during the shipping process.

With these tech solutions, you can get access updates in real-time, giving you complete visibility and time to respond or react. This goes a long way toward preventing delays and disruptions in the shipping process. You will also benefit from exploring other shipping routes and rail lines that minimize delays.

2. Invest in Collaboration

It is important to consider strategically collaborating with operators who enjoy a good relationship with rail carriers. Good operators help move information seamlessly between the shipper and the rail carriers, enabling proactive solutions to issues delaying operations. This can help reduce rail transportation costs significantly.

3. Invest in Creating an Agile Supply Chain

Supply chain agility means supply chain resilience. This means you have a flexible supply chain that adapts easily to changing circumstances. Most of the aforementioned operational challenges can be annoying, especially when other parts of the supply chain rely on the transported cargo. Therefore, getting the supply chain to the point where such challenges don’t have to hobble it is vital.

Doing this means running an efficient inventory management and warehouse operation. It will also necessitate ample investment in technology for visibility over intermodal shipments across different rail carrier options. As we mentioned earlier, these come in handy to help you avoid situations that could negatively impact your supply chain operations.

4. Optimize Your Shipments

Optimizing your shipments means taking actions such as consolidation and repackaging. This will help you maximize the allocated space and potentially reduce transportation costs. Effective consolidation and repackaging also help improve the efficiency of the entire shipping process and promote sustainability in your operation. Shipment optimization also comes in handy if you have too many bulk commodities for a single rail car.

How Terminal49 Can Help Overcome These Operational Challenges

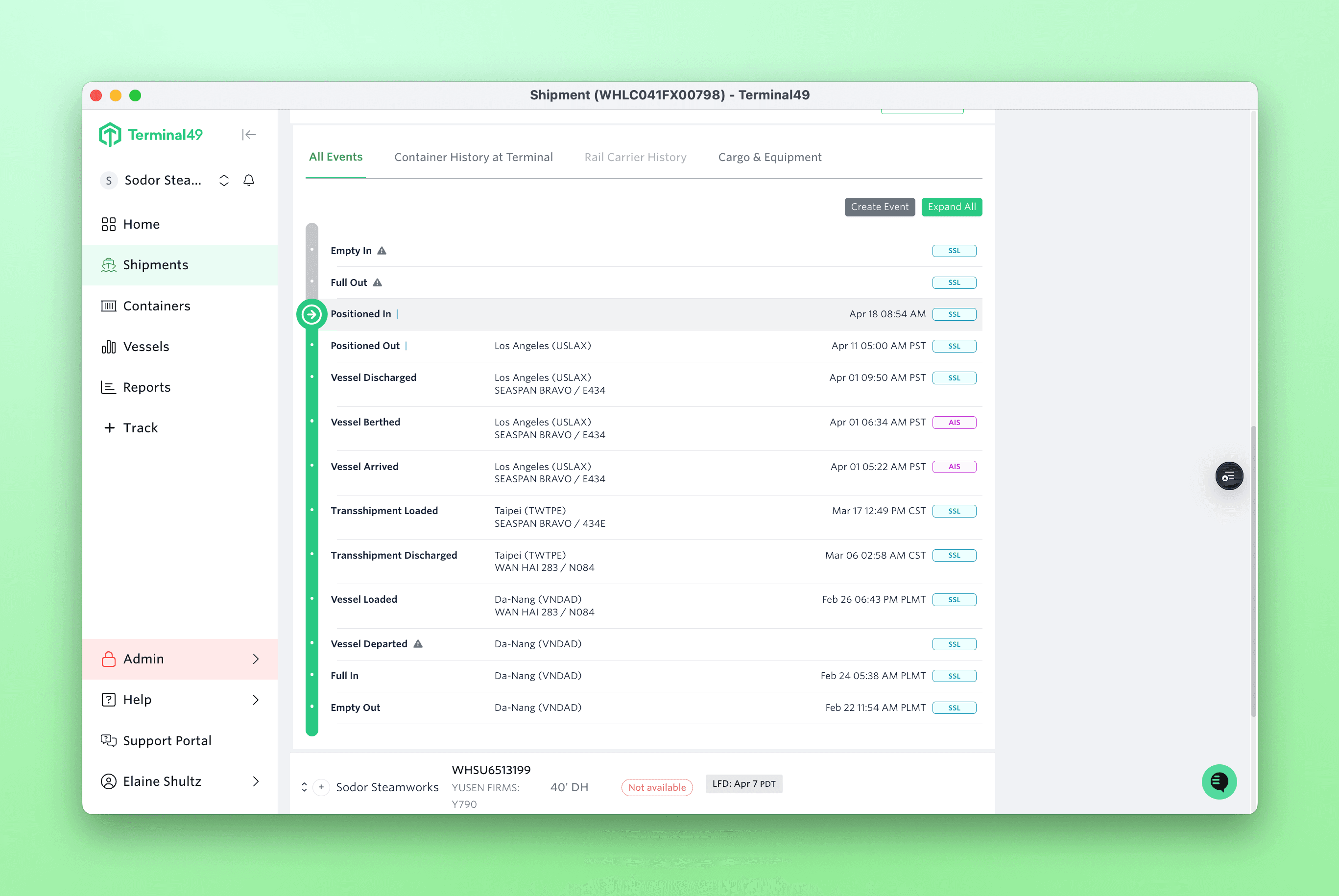

We know the operational challenges are real. But we also know that you can keep a tight grip on your intermodal shipping operations with the right visibility. Terminal49 is a control center for tracking your cargo throughout the shipping process.

With over a billion milestones tracked, we know a thing or two about keeping an eye on your cargo while ensuring your cost is low. The Terminal49 dashboard lets you track all key milestones of your cargo's journey. With it, you can get details such as holds, fees, pickup status, and more in one spot. With our integrations, you have the entire North American import supply chain at your fingertips. This will allow seamless access to comprehensive information about your cargo, no matter where it is on the continent.

Frequently Asked Questions

Q1: What can I do if my shipments are experiencing frequent delays due to rail congestion?

Though more common than many assume, rail congestion can harm shipping operations. To avoid it, consider exploring alternative, less congested, and multimodal routes or partnering with a carrier that has an extensive rail network. This will allow you to combine rail with truck transportation.

Q2: How can I optimize my packaging for freight railroads and intermodal shipping?

Proper packaging is essential because it helps minimize wasted space and maximizes the number of goods a container can carry. Invest in tech solutions that allow you to make suitable simulations and calculations properly. Consult your carrier or a 3PL provider for specific packaging guidelines.

Q3: What emerging technologies can help me overcome rail and intermodal shipping challenges?

Technology keeps advancing, giving us the edge in the transportation business. Thanks to that, more businesses can ship freight efficiently. To get it right with intermodal shipping, explore technologies like real-time data analytics for optimizing scheduling and resource allocation and automation tools for streamlining documentation and communication.

Q4: How can I stay informed about potential disruptions in the rail industry?

You can do this by monitoring industry trends, infrastructure projects and building materials, regulatory changes, and weather forecasts that might impact rail operations. This way, you can proactively use your strategies when shipping freight and develop contingency plans to address potential disruptions.