In the last few decades, a rise in global incomes has led to a nutritional transition that has seen a simultaneous increase in the demand for and consumption of imported fresh food and other perishable items. With the trend expected to continue, perishable items will account for a larger percentage of the shipping operations. However, managing the shipment of these perishable goods can be challenging.

A primary reason is that these shipments are highly susceptible to damage, and even a slight delay can be dangerous. Perishable goods’ sensitivity to the external environment means that they cannot be put in regular shipping container(s) but rather in refrigerated containers. Reefer containers, or reefers, in short, are temperature-controlled containers that are the primary means of transport of perishable and temperature-sensitive freight.

Moving reefer container freight is expensive due to the scarcity of such containers and the expense of maintaining the desired temperature and atmospheric pressure within them. This makes it paramount for shippers and importers to invest in and integrate solutions that give them more control over the shipping process. Better tracking and monitoring of reefer container freight allows them to mitigate risks effectively and make informed decisions that ensure little to zero waste.

This article will explore some of the best practices for managing perishable goods and Terminal49 solutions that can leveraged to manage the shipping process.

The Step-by-Step Process to Monitoring Perishable Freight

Shipping perishable goods can be a complicated process, primarily because of the nature of these products. However, with innovation, advancements in technology, and more demand than ever, there are strategic approaches that can be leveraged to ensure a seamless process.

Some of them are:

1. Thorough Pre-Shipment Planning

Like any other industry, success begins with meticulous planning and coordination to ensure a seamless process. For example, accurate and well-detailed documentation is always needed during shipping. It is useful for government officials like the customs authorities, who must check and verify the shipment details. However, it is also necessary to outline specific temperature requirements, handling instructions, and any regulatory considerations that may be important during the handling process.

During the planning phase, the stakeholders must ensure that the right shipping mode and method, including refrigerated trucks and reefer containers, are selected. Routing optimization is also critical because these shipments are time-sensitive. Finding the best possible routes and avoiding routes prone to delays or heavy congestion helps minimize transit times.

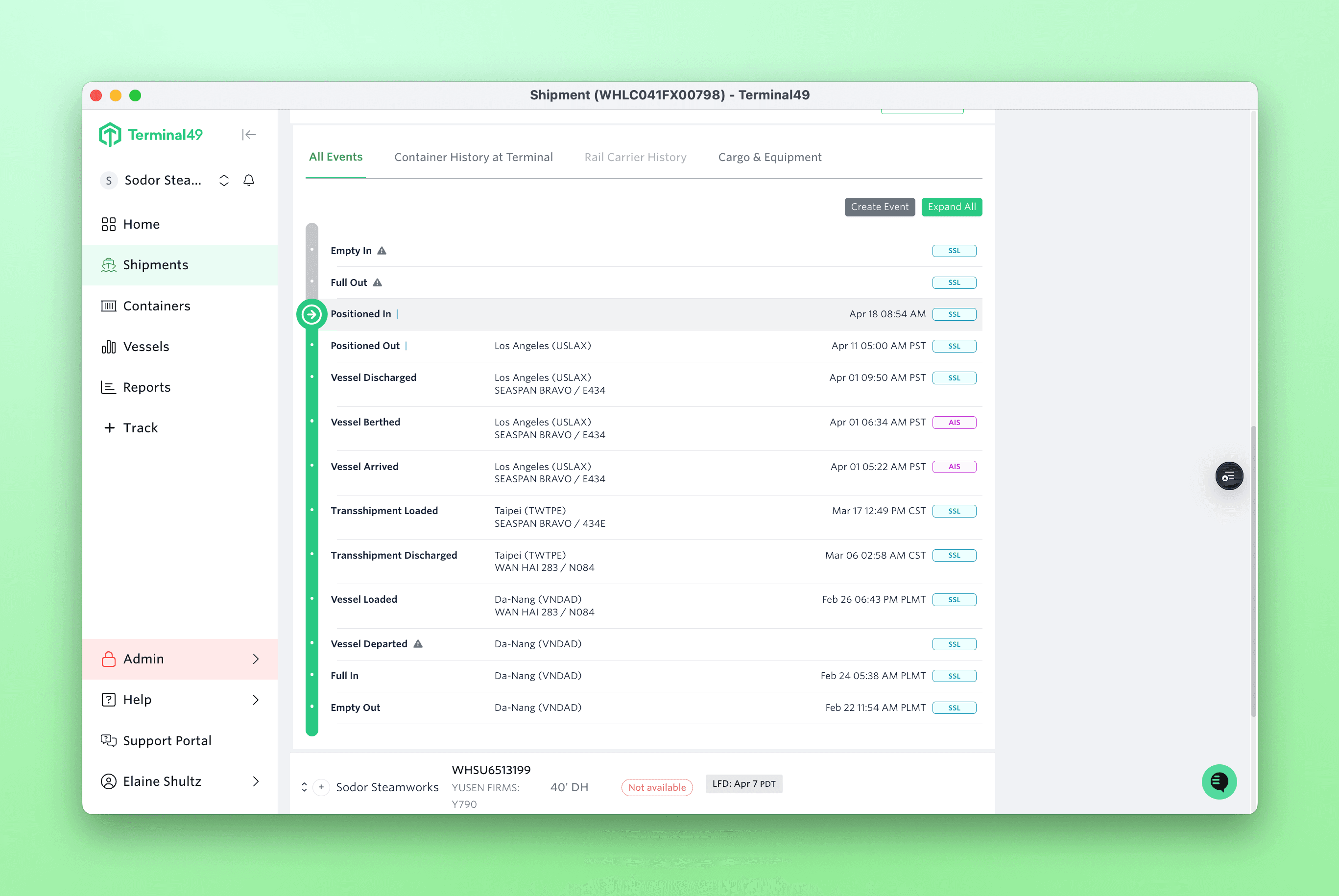

However, even the best-laid plans can be worthless without proper control. This is why more shippers than ever trust the Terminal49 platform. It gives importers better control over their perishable goods, and helps with exception management when freight moves do not go your way. They can coordinate and track their shipments via the container milestones application, including FDA clearance, customs release, and vessel estimated time of arrival (ETA).

2. Robust Temperature Monitoring and Control

Refrigerated cargo or perishable goods like food(dairy products or meat) and pharmaceutical products usually require transportation or shipping at an ideal temperature. This is one major reason for the complicated nature of shipping perishable goods. Controlling the temperature was difficult in the past, but modern technology has made it easier to remove heat and ship within desired conditions.

Today, shippers can effectively monitor the temperature conditions of these shipments from remote locations and take proactive steps to mitigate challenges such as a drop from the required temperature range. Modern temperature monitoring devices, such as data loggers, sensors, and telematics systems, provide precise readings and real-time alerts, allowing quick corrective actions and informed decision-making.

3. Efficient Transportation and Logistics

Efficiency in the modern transport and logistics process boils down to transparency and visibility. With these two, all stakeholders can move seamlessly and complete their processes simultaneously. For instance, through the Terminal49 visibility solution and container milestones, a customs broker can tell when the shipment will arrive through an accurate ETA notification, which can be updated in real time if there are any delays.

It enhances effective planning and execution of the customs clearance process, ensuring drayage companies have refrigerated trailers in place to continue shipping without unnecessary delays. Visibility and transparency also make the shipping process much more flexible. Shippers and robust tech solutions can analyze data in real-time to forecast any delays or disruptions impacting the shipped products.

This way, all stakeholders can make the necessary adjustments to ensure the products reach their desired destination on time and under the right circumstances. Transparency and visibility through the Terminal49 application streamline communication between shippers, carriers, and receivers, ensuring everyone is aligned on delivery timelines and requirements.

4. Contingency Planning and Regulatory Compliance

It's great to be able to monitor time-sensitive and perishable shipments effectively. However, this may be for nothing without preparing for unexpected situations, such as delays or equipment malfunctions. Shippers must set up backup transportation options and predefined protocols for handling emergencies and communicate them to all stakeholders. This will enable them to mitigate risks and prevent costly losses.

Adherence to refrigerated cargo safety and transportation regulations is essential to avoid penalties and protect public health. Standards like the Food Safety Modernization Act (FSMA) and Hazard Analysis and Critical Control Points (HACCP) provide guidelines to ensure shipments meet legal and safety requirements.

Managing Perishable Goods Through Reefer Container Milestones

On the Terminal49 platform, shippers of perishable products have access to real-time, high-quality data on their freight whereabouts. This tracking enhances freight management, allowing shippers and importers to ensure temperature-sensitive goods are delivered on time and in optimal condition without significantly impacting their shelf life.

What are some of these solutions?

1. Real-Time Shipment Monitoring

Terminal49 tracks key milestones for shippers, including FDA clearance, customs release, and vessel arrival times. The platform also provides regular updates and alerts that ensure the shippers are always informed about shipment status, allowing them to address any delays promptly.

2. Environmental Condition Tracking

Terminal49 can integrate with IoT sensors to monitor temperature and humidity within cargo containers. It also provides timely alerts on deviations, allowing shippers to take quick action to prevent spoilage or damage to goods.

3. Centralized Data Access

All shipment information is consolidated into one dashboard, giving users a clear view of their cargo movements. Historical data is stored for review, helping businesses improve planning and identify potential risks.

4. Accurate Arrival Estimates

Predictive technology accurately calculates estimated arrival times, allowing businesses to coordinate unloading and distribution without unnecessary delays. This helps reduce waiting times and prevents additional costs.

Wrap Up

Properly managing perishable goods such as food, pharmaceuticals, and chemical materials in standard reefer containers is critical for industry businesses. Companies can protect their shipments, save costs, and maintain customer trust by implementing strategic planning, leveraging advanced technology, and focusing on efficiency and compliance. Investing in these practices safeguards cargo and enhances overall business performance. Connect with Terminal49 to see the difference we can make to your operations.