Why Customs Delays Are a Serious Risk for Construction Equipment Imports

For construction companies and equipment shippers, customs clearance is one of the most unpredictable and potentially costly stages of international shipping. Even minor documentation errors or misclassifications can lead to serious hold-ups — impacting project timelines, budgets, and client relationships.

Unlike retail shipments, construction equipment imports are often time-sensitive and capital-intensive. A delayed excavator or crane could bring a multimillion-dollar build to a standstill.

That’s why customs clearance for construction equipment demands precision, planning, and full supply chain visibility. In this guide, we’ll break down the most common causes of delays, and how to mitigate them with smarter processes and tech tools like Terminal49.

Understanding the Most Common Causes of Customs Delays for Construction Equipment

Customs holds can occur for several reasons, but most can be traced back to documentation, valuation, or classification issues. Here's what to watch for:

1. Documentation Errors in Heavy Equipment Shipping

Poor paperwork is one of the leading causes of customs clearance issues. Missing or incorrect commercial invoices, packing lists, or certificates of origin can lead to extended inspections and even fines.

📌 For construction machinery, your documentation must clearly describe:

- Machine type and specifications

- Serial numbers

- Intended use

- Any required permits or compliance certificates (e.g., emissions)

Terminal49 can alert you to missing or incomplete documents before a shipment reaches the port, reducing hold risk.

2. Valuation Discrepancies and HTS Code Mistakes

When customs authorities review shipment value declarations, they often perform their own assessments. If your declared values don’t align, expect delays.

Equally critical is choosing the correct Harmonized Tariff Schedule (HTS) code. Misclassifying a generator or bulldozer can lead to tariff miscalculations and further scrutiny.

Best practices:

- Use the correct HTS code specific to construction equipment

- Attach supporting documentation (invoices, contracts, spec sheets)

3. Misclassification of Specialized Machinery

Heavy equipment often includes specialized or hybrid machines. Improper classification not only affects duties but may also trigger manual reviews. For example, classifying a mobile crane as “general machinery” can raise red flags and cause unnecessary delays.

4. Inspections and Examination Holds

Random or targeted customs inspections are common for high-value shipments like construction equipment. These can delay your shipment for days unless your paperwork and supply chain communication are watertight.

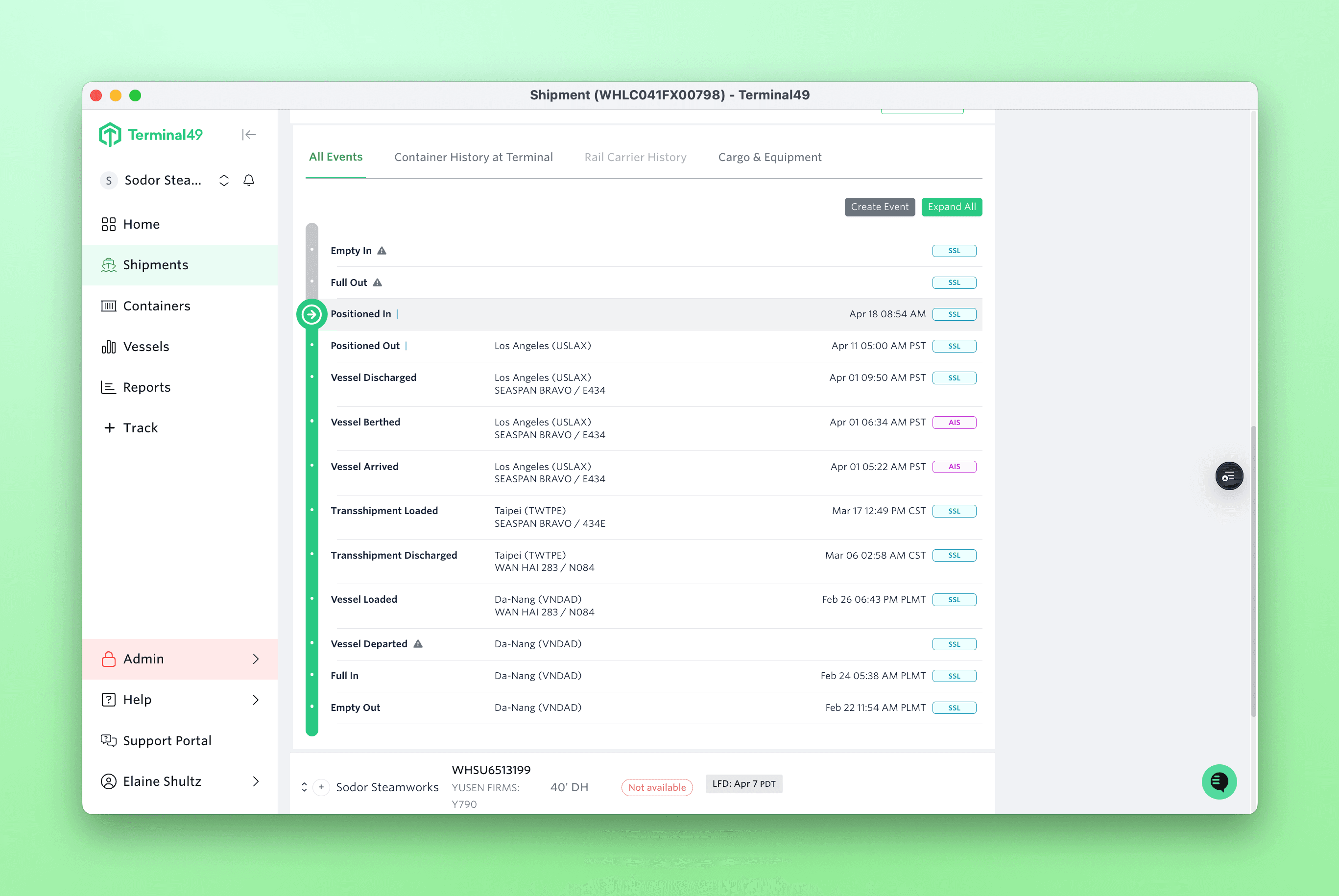

With Terminal49, you can:

- Get real-time alerts when shipments are flagged

- Monitor inspection milestones

- Take immediate action to reduce downtime

5. Port Congestion and Operational Bottlenecks

Customs delays are sometimes caused by factors beyond your control — like port congestion, strikes, or limited drayage capacity. These issues compound when paired with documentation or classification problems.

Terminal49 aggregates port data and congestion trends, helping you reroute or adjust schedules ahead of time.

Construction Equipment Import Requirements: What You Need to Get Right

Customs delays can be particularly disruptive in the construction industry, where equipment is often required on-site within tight project timelines. A delayed shipment of excavators, cranes, or specialized machinery can stall an entire build. However, with the right tools and industry-specific strategies, contractors and importers can reduce these risks significantly.

1. Accurate and Complete Documentation

For construction equipment, paperwork must do more than state origin and destination — it must clearly describe machinery specifications, serial numbers, and intended use. Incomplete or inconsistent documentation, especially around large or specialized machines, is one of the most common causes of customs delays.

Use standardized templates and checklists tailored to heavy equipment imports, and ensure that required permits — such as emissions compliance or safety certifications — are in place.

2. Proper Valuation and Classification

Customs officials pay special attention to the declared value of high-ticket items like bulldozers or tower cranes. Incorrect HTS codes or vague descriptions can raise red flags. For example, misclassifying a generator as general machinery rather than power equipment could lead to tariff miscalculations and rework. Maintain clear records (invoices, contracts, specs) to support your declared values.

3. Advance Planning and Communication

Construction timelines don’t leave much room for customs delays. Planning shipments well in advance is essential to absorb any unexpected processing time. Early coordination with customs brokers and freight partners can also preempt issues around oversized or overweight equipment. Terminal49 facilitates smoother collaboration by keeping all stakeholders aligned through real-time updates, reducing the chances of last-minute scrambling.

4. Working with a Licensed Customs Broker

Importing construction equipment often involves complex regulatory requirements, such as compliance with environmental standards or import licensing for specific types of machinery. An experienced customs broker who understands these nuances can help avoid missteps.

5. Utilizing Technology

Construction shipments are time-sensitive, bulky, and high-value — meaning delays are not just inconvenient but expensive. Platforms like Terminal49 are built to handle the demands of such high-stakes logistics.

With Terminal49, importers can:

- Track critical customs milestones (e.g., ISF filing, customs holds, inspections) in real time

- Receive automated alerts about missing documents or potential delays

- Centralize shipment and broker communication in one dashboard

This not only improves visibility but also allows contractors and logistics teams to take corrective action before delays escalate. By reducing downtime at the border, Terminal49 helps keep projects on schedule — and budgets in check.

6. Participating in Trusted Trader Programs

Programs like the Customs-Trade Partnership Against Terrorism (C-TPAT) allow shippers to enjoy a more streamlined shipping process. There are fewer inspections, and even where there are, they are entitled to expedited processing. Programs like these reward trusted importers with streamlined clearance procedures, enhancing shipment reliability.

How Terminal49 Helps Keep Construction Projects On Schedule

Terminal49 is built for shippers moving high-value, time-sensitive cargo like construction equipment.

With our platform, you get:

- Real-time visibility into container milestones and customs events

- Automatic updates when shipments are flagged or delayed

- A centralized dashboard to manage documents, brokers, and alerts

- Tools to reduce demurrage, detention, and compliance risks

Customers use Terminal49 to cut down delays, reduce manual tracking, and get equipment where it needs to be — faster.

Final Takeaways for Heavy Equipment Importers

Customs clearance for construction equipment doesn’t have to be a constant bottleneck. With the right documentation, classification, and tracking tools, you can avoid delays and keep your project timelines intact.

Key strategies to remember:

- Get your paperwork right

- Use accurate HTS codes and proper valuation

- Plan ahead with brokers and partners

- Automate customs tracking with a platform like Terminal49

Ready to avoid customs delays and streamline your next shipment?

Schedule a demo with Terminal49 and see how real-time visibility can keep your operations moving.

FAQs

What documents are required to import construction equipment into the U.S.?You’ll need commercial invoices, packing lists, certificates of origin, and any applicable compliance permits (e.g., emissions).

How can I speed up customs clearance for heavy equipment?Use accurate classification, ensure complete documentation, and adopt tools like Terminal49 to track customs milestones and alerts in real-time.

What is the HTS code for construction equipment?HTS codes vary by machine type. Always check the HTS Code Database or work with a licensed broker to classify properly.