Before the pandemic, containers offloaded from a ship typically sat on a dock (awaiting pickup via truck) for an average of four days. Containers picked up and transported via train typically dwelled in port for less than two days.

Today, supply chain backlogs, reduced worker capacity in ports (still due to COVID 19 issues), and the inability of shippers to synchronize truck & rail handoffs have exacerbated delays. The Port of Los Angeles recently reported that there were 94,142 containers sitting on its docks. Almost 40% had been sitting for more than nine days. Approximately 8% had been sitting for 12 days. And 30% (more than 28,000 containers) — had lingered for at least 13 days.

Once a shipping container arrives at a terminal, it can only sit “for free” in the port for 3-5 days, before it needs to be picked up (by truck or train) to head to its final destination. If containers are not picked up within the allotted timeframe, a series of charges can be assessed to the consignee, or receiving party. These charges include:

Per Diem Fees – occur when the importer has picked up the container for unpacking but the empty container hasn’t yet been returned to the shipping line (within the agreed upon time).

Demurrage charges – occur when a full container has not exited the port within the allowed number of “free days” offered by the shipping line. The term Demurrage traces its origins to the French word “demeurer”, which essentially means “to be late”.

Incremental Container Dwell Fees – today, some ports in the United States are charging incremental fees up to $100 per day (for every lingering container). These incremental fees start at 9 days for containers awaiting pick up via truck, and just 3 days for containers awaiting train delivery. The fees can increase depending on how long a container sits.

For shippers with hundreds (or thousands) of containers, these daily fees cut into profit margins in a manner that can’t simply be passed on to consumers. Careful planning is required to precisely identify where and when containers are scheduled to arrive in port - and information is the key to this planning.

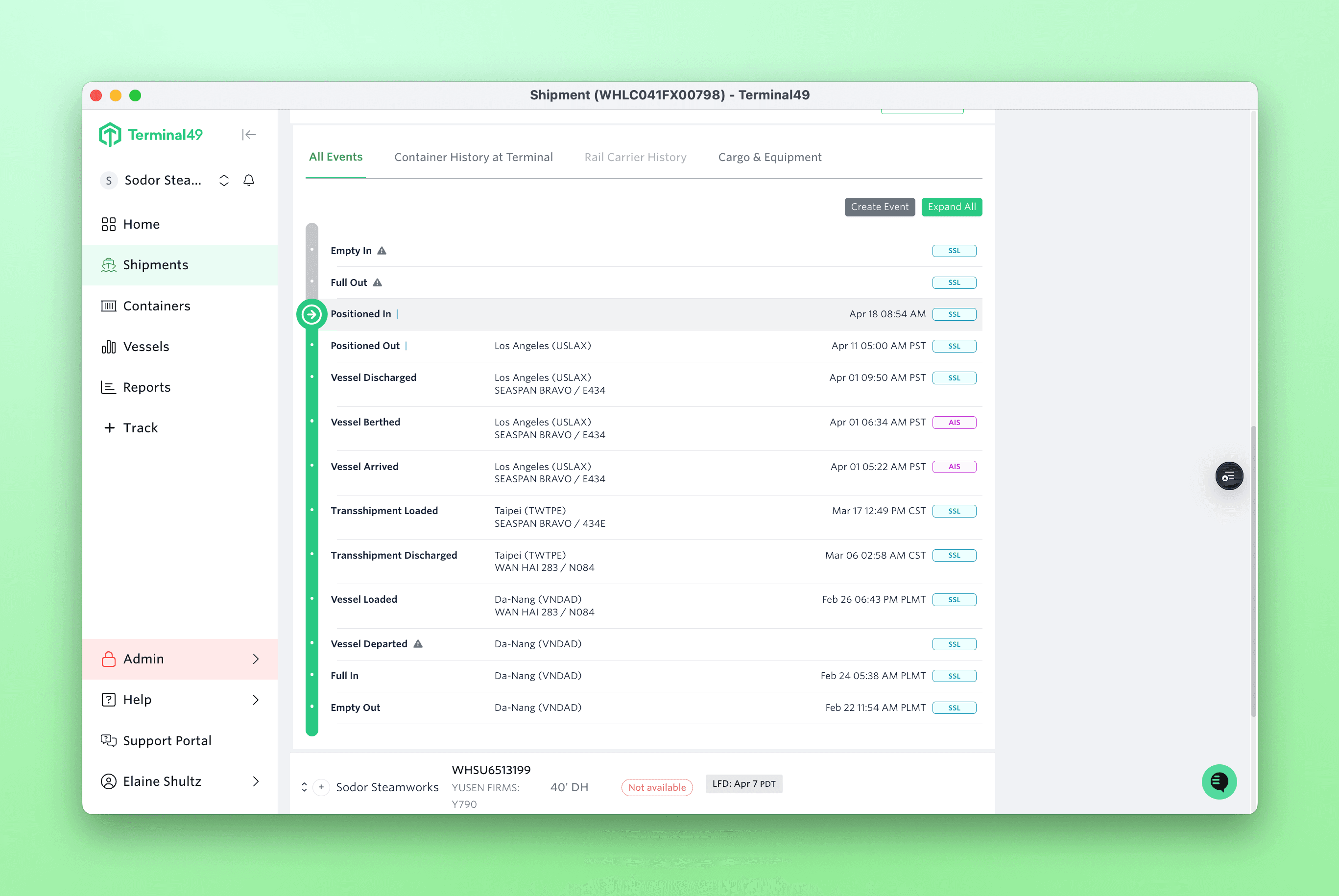

Technology assets such as Terminal49 offer shippers the visibility they need to track containers on the ocean and gain the lead time they need to synchronize pick-ups at the dock. Terminal49’s software platform accesses more than 97% of all global container traffic. It provides status updates from all major steamship lines, every port & terminal in the USA, and a wide range of trucking companies.

The visibility provided by Terminal49’s software prevents users from having to track down information or chase people for updates. Customizable alerts inform shippers when their containers have been offloaded. It tells them where their containers are staged. It notifies them when containers are ready to be picked up. Most importantly, it provides this information in a timely manner so that shippers can coordinate truck (and rail) pick-up to avoid demurrage, per diem and incremental container dwelling fees.

Data & information are the most important tools that carriers have to avoid wasteful fees. The ROI for the Terminal49 software was easy to calculate even before ports started imposing incremental dwelling fees. Today - and until the supply chain crisis passes - the ROI is even greater. To learn more or to start tracking containers today, visit: https://app.terminal49.com/register.