Supply chains today are exposed to a high level of competition that supply chains before the 21st century may not have encountered. This is why, many times, it feels like there is no room for mistakes in the supply chain, and businesses invest tremendous amounts to improve their supply chain efficiency. There are different techniques a supply chain manager might use to improve the efficiency of the supply chain operation, but few are as impactful as data standardization.

Since the industrial revolution, the efficiency of business and supply chain operations have always been tied to the level of data standardization the business is exposed to. However, data standardization was less refined and precise than it is for modern supply chains. This is primarily because of the high level of competition that modern supply chains are exposed to. If they hope to stand out or gain a competitive advantage, they would need to rely on much higher levels of data standardization to run an efficient supply chain.

Knowing how important data standardization is to global supply chains that wish to improve their efficiency, we must address the how. This article will explore data standardization's role in improving logistics management and supply chain efficiency, especially for business logistics that rely on it.

What is Data Standardization?

The thing about data is that it can be interpreted in several ways. Different businesses might interpret different meanings from the same data. More than that, different units within the business and its supply chain might interpret the same data to mean different things. As you can imagine, this will create confusion between those units and inevitably slow down or disrupt supply chain management.

This is where data standardization comes into play. It is the creation of a universal language or format for the storing, sharing, and interpreting of information. For example, in the United States, most supply chains will use feats instead of meters. Other formats include “in stock” instead of available or using a “12-digit” format for product codes.

With these formats adequately in place or included in the SOP and communicated to all parties (internal and external) involved in the shipping, logistics, or supply chain management, they will be able to use them as needed and in turn. Data standardization improves data quality, leading to improved efficiency across the board.

Improving Logistics and Supply Chain Efficiency Through Data Standardization

Supply chain efficiency refers to a supply chain's ability to utilize resources such that costs are reduced and profits are maximized. As mentioned earlier, the competitive environment is as intense as they come. The nature of the market is such that much of this competition is no longer between businesses but between their supply chains.

For most supply chains, the customers can be easily persuaded to patronize other businesses and their supply chains. So businesses spend so much on ads, and the supply chains cannot afford mistakes. There is a greater call for efficiency. Here are some ways data standardization can help.

1. Improved Communication

Imagine talking to a carrier or a shipping operator, and you are asked the length of the preferred container you want to use for transporting your goods. You reply 30 without saying the “feet” part out loud, which is understandable. You expect them to know what you mean. But what if the carrier misinterpreted that to mean 30 meters?

That seemingly little mistake can cost you more than you anticipated and, in many other cases, could jeopardize your shipping or supply chain operations. That is the impact of wrong communication. However, with data standardization, that can be fixed. By standardizing data across your supply chain, you can improve communication, thereby improving the efficiency of the entire supply chain.

2. Reduced Errors

By standardizing data across your logistics and supply chain operation, you can empower all parties involved in the process to interpret data more accurately, which will, in turn, help them reduce errors. Using the supply chain operations reference from earlier, the carriers or operators are prone to mistakes just because of a lack of clarity on the standardization model of the supply chain.

Errors in the shipping, supply chain, and even that of inventory management processes will lead to wrong deliveries, product damage, wastage, and, in many cases, supply chain disruption. These can cost the business and supply chain a lot of money, which can be very difficult, especially when running on thin margins.

3. Improved Decision Making

Decision-making is a huge part of any supply chain operation. However, consider what happens when these decisions are made with the wrong information set. As we have seen from the earlier illustration, a slight misinterpretation of data could mean a lot of trouble for any supply chain. For a complex supply chain operation with a lot of moving parts that necessitate on-the-spot decision making, that can be very costly.

However, with data standardization, this becomes so much easier, primarily because all parties involved in the decision-making process have access to the right information in the right format. This makes them better equipped to make better decisions throughout the supply chain process.

4. Improved Visibility and Transparency

Although transparency and visibility are in high demand for modern supply chains, achieving them is mostly possible when you have access to the correct type of information. For instance, during a shipping operation, you may want to track your containers and know how long your vessel will take to get to its destination. Such information is calculated using two key details: the distance and speed of the vessel.

However, with the wrong standardization, you will get the wrong information, which could impact subsequent plans, processes, and supply chain strategy. It will also prove difficult to measure supply chain performance metrics. Visibility and transparency in the supply chain are not only reliant on real-time information but also on the nature and standardization of that information.

5. Enhancing Supply Chain Automation

Automation and artificial intelligence are big deals for most modern supply chains. However, to effectively automate supply chain processes, you will rely heavily on the use of data, and for it to be effective for your supply chain or improve its efficiency, this data must be standardized. This will enable it to properly receive and process the right type of information that will be helpful to the supply chain operation.

How Can Supply Chains Ensure Data Standardization?

Because data standardization is important to improve supply chain efficiency, it is the responsibility of the supply chain to ensure it is in place throughout its operations. The supply chain may ensure data standardization throughout its operation in two key ways.

1. Embrace Industry Standards

The standards may differ depending on the industry where your supply chain is located. Because you will be interacting with the different entities in that industry, embracing or adopting its data standardization format is necessary.

2. Create Unique Data Standards

There are times when the supply chain may require unique standardization of data. This is usually the case for unique or very large supply chain operations that integrate data from different sources. In this case, you can create a data standardization structure in partnership with all relevant stakeholders. These data standards must also be communicated to all parties and departments involved in the supply chain. It can also be made a core part of the standard operating procedure.

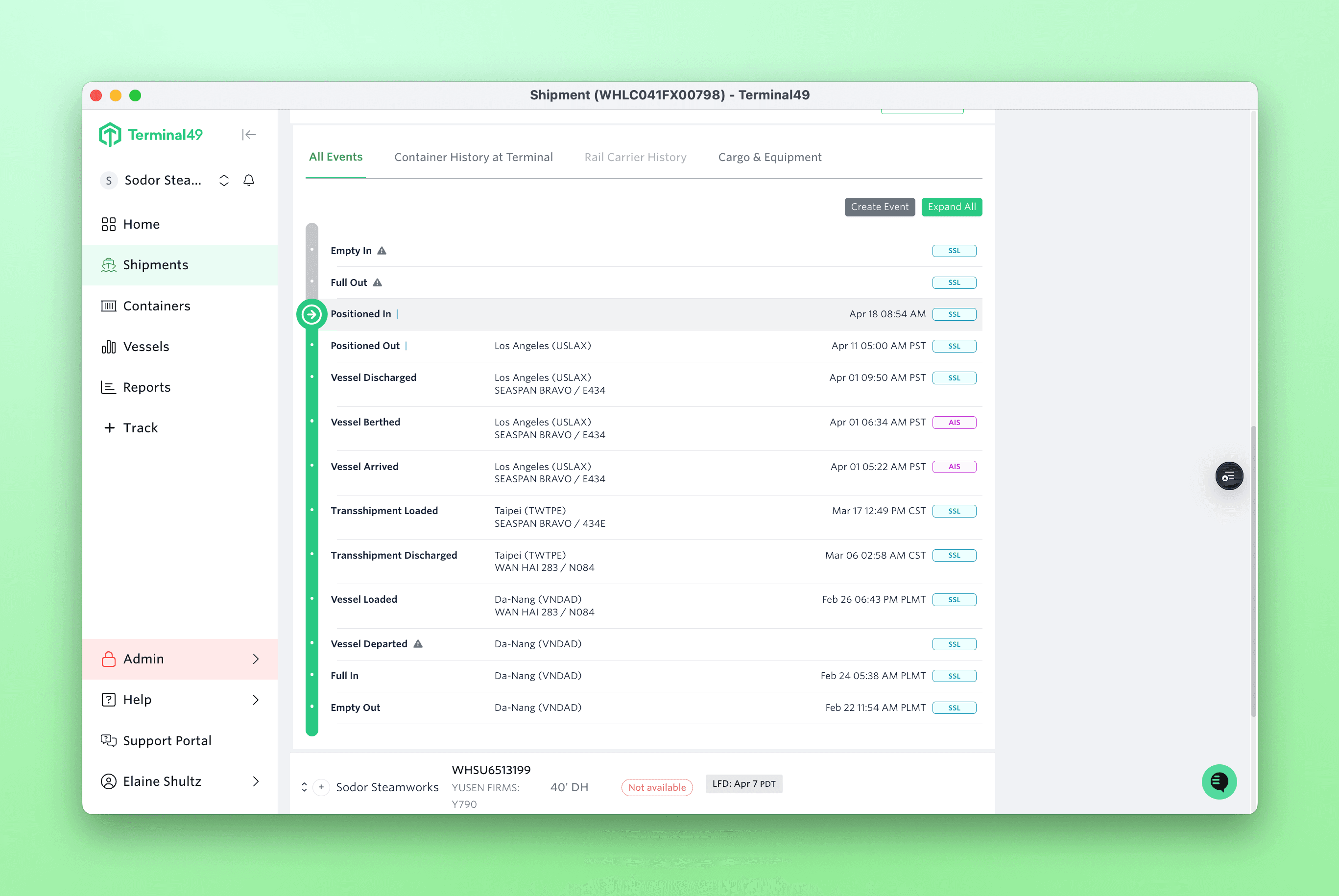

How Terminal49 Can Help Your Supply Chain Improve its Efficiency Through Data Standardization

Data standardization is important if you are seeking to improve and measure supply chain efficiency. However, it can get cumbersome, especially when dealing with different forms of data from different sources. With Terminal49, integrating, processing, and standardising this information becomes much easier.

Terminal49 offers you a platform that can standardize hundreds of data from multiple sources and manage from one control center. With this, you can efficiently plan, streamline, and enhance the visibility of your supply chain operations.