Freight Forwarder Saves 300+ Hours and Thousands of Dollars a Month on Container Tracking

Learn how Terminal49 help a mid-sized freight forwarder, customs broker and NVOCC automate container data management and improve customer trust

The brokerage management team moved from a manual, outdated, cumbersome, and costly container tracking workflow to an automated, accurate, and reliable process with Terminal49. As a result, they:

- Saved roughly 300 hours per month in employee time

- Eliminated thousands of dollars in demurrage, rescheduling and late fees per year

- Built stronger value for their customers, improving customer trust

About the Customer

A mid-sized freight forwarder, U.S. Customs Broker, and licensed NVOCC providing ocean and air freight transportation and logistics services to SMB and mid-market U.S. importers.

Their goal is to bring freight visibility to small and mid-sized U.S. importers (typically importing fewer than 1,000 containers each year) who don’t have the IT infrastructure, budget, or industry experience to efficiently manage freight and customs logistics. “Small to medium size importers live by their shipments so if a container is two or three days late, or if there are delays which they are not immediately alerted to, it will have a significant impact on their business,” said Spencer. “These companies aren’t well versed in the complexities of freight timing, delivery scheduling, and terminal requirements. Our customers depend on us to be their trusted partner in freight logistics.”

A Cumbersome, Outdated, and Costly Workflow

Today, there is no industry standard method for collecting, aggregating, and searching freight data. Anyone needing access to shipment information has to manually search through dozens of websites to uncover container milestones. They use this data to respond to any changes in ETAs, log container statuses (typically in spreadsheets), and then share status updates with impacted vendors and customers. It’s an outdated and inefficient process.

Several of TXC’s staff, including Brokerage Manager Jon Shellabarger and his team, would spend countless hours a week tracking customer containers across steamship, terminal, and rail websites. “One person on my team would spend about 3 hours each day trying to track down container statuses and ETAs, and then put the data into the customer's preferred format,” recalled Jon. With data fragmented across multiple sites, and often outdated and incomplete, team members would need to constantly check and recheck container statuses before relaying updates to their customers. It was a cumbersome and time-consuming process, and error-prone.

“Someone on my team showed me how they managed their process and they had 27 tabs open in their browser,” said Spencer. “It was very reactive, duplicative, and didn’t quickly highlight what was at risk.”

Being able to identify containers at risk of delay is critical to the health of the customer’s business, and TXC’s. If a customer’s import container was missed, or not picked up on time, the customer could incur demurrage and rescheduling fees. Even a small amount of human error in ETA or status updates could have costly consequences for both the customer, and TXC. “We would absorb thousands of dollars a year in customer demurrage,” recalled Spencer.

While impactful to the business’s bottom-line, Spencer and his team were more concerned about the longer-term impacts on customer trust. They needed a reliable way to track and manage customer containers at scale.

Automating Container Tracking and Management

TXC believed that with recent visibility on the global supply chain congestion, that there had to be strides in innovation to improve container tracking. They set out to find a modern solution, and were eager to find a company who could feel like a long-term partner. They had clear requirements for the solution. It needed to:

- Have accurate and reliable container milestones from carriers and terminal data

- Different views of the data, in particular they needed to be able see real-time ETA alongside original ETA

- An API that would allow them to pull in data into their own systems

- Be easy to use for everyone in their team

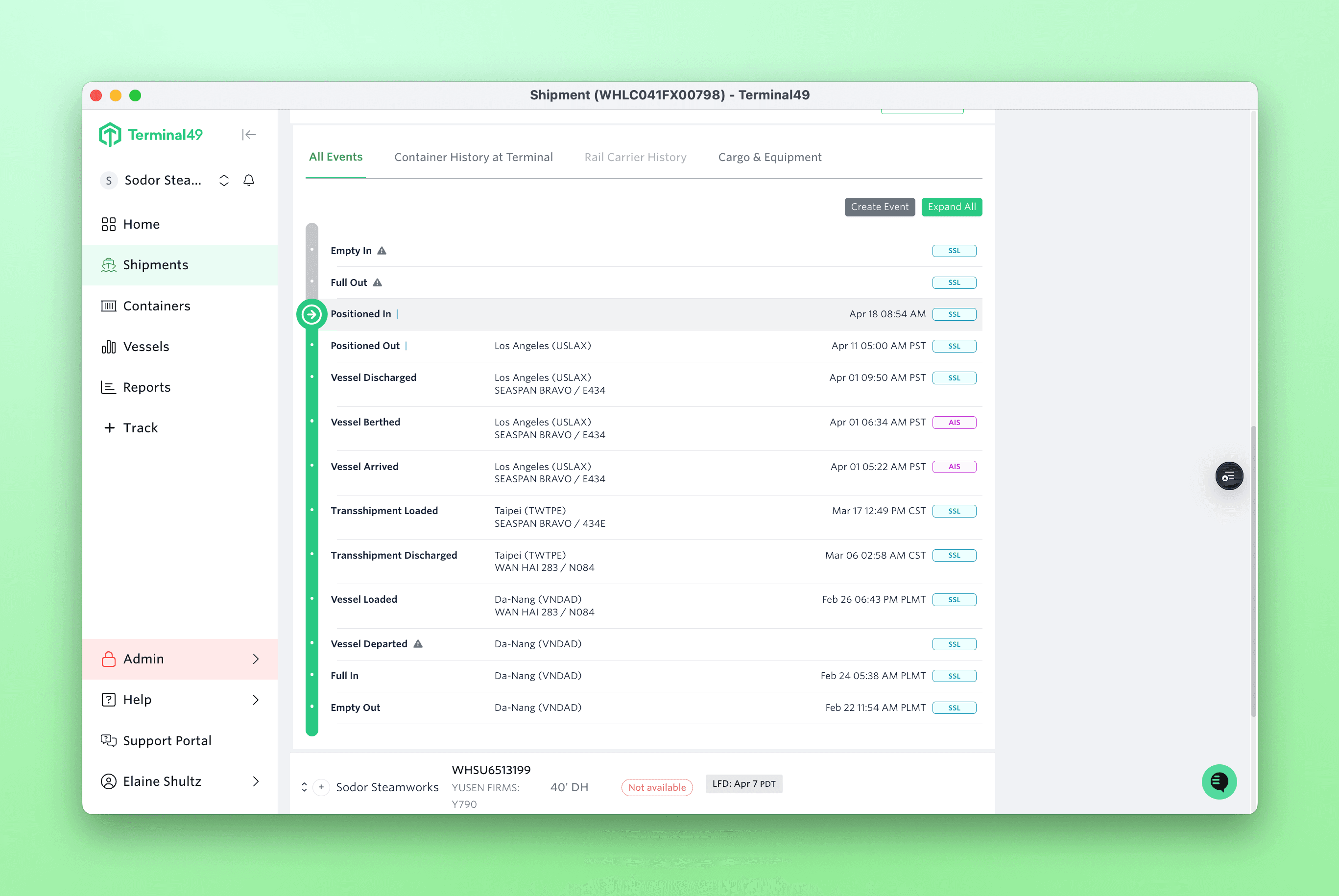

Spencer and Dan evaluated a few solutions and ultimately decided that Terminal49 (T49) had the most comprehensive offering. While they found T49 easy to use and intuitive, what really convinced them was the centralized and searchable dashboard - a single view of terminal and carrier data built from tight integrations with steamship and terminal sources. They were also impressed with how quickly they could identify containers at risk.

They began testing Terminal49 with the brokerage management team to see how those on the frontlines of managing customer container data would respond. The initial feedback was resoundingly positive. “It’s extremely time-consuming to search terminal, steamship, and rail websites just to get an update on a container’s status,” said Jon. “When we tested Terminal49, I was amazed to see everything in one place.”

Because container data has historically been unreliable and difficult to access, there was some initial skepticism about the integrity of T49’s data. Inaccurate data can be costly, so the team needed to be convinced that T49 wasn’t too good to be true. “We use this data to make important decisions on behalf of our customers, so we need to be able to trust and depend on what we’re seeing,” said Spencer.

Terminal49 measures container data across three vectors - completeness, accuracy, and latency - which helped alleviate some of the initial concerns.

- Completeness. We offer a wide coverage of data sources and milestones directly from ports and terminals. We cover 98% of all global container traffic.

- Accuracy. We’re always improving and filtering out inaccurate and incomplete data.

- Latency: We provide container events and milestones as quickly as possible. We guarantee 2hr terminal data freshness and 6hr steamship data freshness.

The team cross-referenced the T49 data with various websites, “we actually tried to break T49,” joked Spencer, and ultimately determined the efficacy of what they were seeing. “Having the ability to view terminal data separate from ocean carrier data, with time stamps, gave my team confidence to trust the data and use it to make more informed decisions,” he said.

About 15 people are responsible for tracking and managing TXC’s customer’s freight cargo, and each person has access to T49. They filter data by client so that they can quickly track their customers' containers and mitigate any risks.

“In logistics, you have to expect that things will go sideways,” said Spencer. “How quickly you react saves time, resources, and money. I check ‘containers at risk’ first thing every morning so that we can address and prioritize any known issues.”

Saving Hundreds of Hours, Thousands of Dollars, and Improving Customer Trust

T49 has become an essential part of TXC’s services, and checking the dashboard is a natural part of the brokerage management team’s workflow. “We now have one location with detailed information on each of the shipments we need to track, which helps us easily identify and prioritize where we need to spend our time,” said Jon. They can now confidently plan and schedule deliveries, minimize demurrage, advise customers of changes in timelines, and complete U.S. Customs Clearance based on T49 data.

Moving from a manual, reactive workflow to an automated and proactive discovery of container ETAs has allowed each team member to get back at least one hour in their day, saving the company roughly 300 hours per month. That time is now spent on more valuable and meaningful work. “Adding Terminal49 to our workflow has been a huge time saving for our team,” added Jon. “And it reduces costly human error.”

But for TXC’s CEO, the benefits go beyond time savings. For Spencer, it comes down to improving customer trust and satisfaction. “A mistake or error can cost our business thousands of dollars, but it can also damage a customer relationship, or worse, we could lose the customer completely,” he said. “Terminal49 has saved us thousands of dollars in demurrage, but more importantly it makes us more credible partners, and helps us build value with our customers.”

TXC has gone from a cumbersome and reactive workflow of pulling, collating, and displaying data in each client’s preferred format, to being able to proactively notify customers based on real-time ETA updates from T49.

“Terminal49 has made our team more efficient and productive,” says Spencer Strader, co-founder and CEO of Trade XCelerators. “We now have access to accurate ocean freight information in one place, which lets us proactively share reliable information with our customers and vendors. Terminal49’s automation has saved us thousands of dollars a year, but more importantly it’s helped improve customer trust.”

Get your containers back on track