The transportation and storage of refrigerated cargo require strict adherence to specific conditions, particularly temperature control. However, just as critical — if not more so — is the time sensitivity associated with these goods. Stakeholders dealing with perishable refrigerated cargo face significant logistical challenges in ensuring freshness and safety. Without the right tools, efficiently managing the transportation process can be challenging, potentially leading to spoilage, financial losses, and operational disruptions.

Such problems can snowball and eventually harm the company's reputation. This article explores strategies for effectively managing time-sensitive refrigerated cargo, reducing spoilage, and cutting unnecessary costs.

Understanding the Risks of Refrigerated Freight

Refrigerated cargo or shipments are highly susceptible to spoilage. Even an hour at the wrong temperature can jeopardize the entire shipment. To navigate these risks, refrigerated shippers must understand the risks involved.

1. Temperature Fluctuations

Different products maintain freshness at various — and specific — temperature ranges. For instance, fresh produce and pharmaceuticals have distinct temperature needs. However, even slight fluctuations in temperature can put these products at risk of spoilage. While knowing the optimal temperature is essential, ensuring consistency across the end-to-end transportation process is even more critical.

2. Humidity and Ventilation

Beyond maintaining the right temperature, there is also the risk of poor humidity and ventilation, which can be equally detrimental to the refrigerated shipment as temperature fluctuations. The lack of proper humidity and ventilation would quickly suck out the ‘freshness’ of a good product. Ensuring adequate airflow within the refrigerated space helps maintain consistent conditions and prevents hotspots or excessive moisture buildup.

3. Transit Time and Delays

The delicate nature of refrigerated shipments would mean a drastic increase in the risk of spoilage when transit times extend beyond their schedule. In real-life conditions, vehicles transporting these goods are exposed to various factors that can compromise freight integrity. Delays caused by traffic, customs inspections, or operational inefficiencies further heighten this risk. To mitigate these challenges, leveraging the right resources and technology to ensure swift, efficient delivery to the final destination while maintaining optimal conditions is crucial.

4. Improper Handling and Packaging

Careless handling during loading, unloading, or transit can compromise the integrity of sensitive cargo. Proper packaging and clear labeling ensure goods are shielded from external factors and handled according to specific requirements.

Key Strategies for Managing Time-Sensitive Refrigerated Cargo

Although managing the time sensitivity of refrigerated cargo is challenging, failure to do so can effectively render the entire logistics effort futile. Fortunately, some strategies can guarantee that success.

1. Pre-Shipment Planning and Preparation

Planning and preparation are the foundational pillars of any successful refrigerated transportation process. During this phase, the shippers must thoroughly inspect goods before loading them into the refrigerated unit, including determining their temperature requirements.

The next step is packaging, which should be tailored to the product's product's specific needs. Appropriate packaging combined with clear, informative labels indicating handling instructions helps ensure safe transport and optimal product integrity, reducing the risk of damage or spoilage.

That aside, the shipper must also ensure that the cargo is pre-cooled to the required temperature, minimizing stress on the refrigeration units. During the planning and preparation phase, the shipper chooses tools, equipment, and partners, such as tracking platforms and refrigerated freight forwarders.

2. Temperature Monitoring and Control

Refrigerated transportation will not be successful without complete visibility and transparency into the temperature conditions of the shipments before and during the freight process. This way, the shippers can make proactive decisions whenever necessary.

Fortunately, modern temperature monitoring devices help us achieve this. These include data loggers and real-time sensors that continuously track temperature conditions throughout the process. Tech solutions like Terminal49's alert systems notify stakeholders of deviations, enabling immediate corrective action. With a clear protocol to manage temperature issues, shippers can prevent spoilage during transit.

3. Route Optimization and Transit Time Minimization

The longer the refrigerated shipment is in transit, the more the risks incurred. This points to the need for efficient and optimized freight routing. When applied successfully, it reduces transit time and lowers the chances of delays. To do that, shippers can leverage solutions such as real-time traffic and weather data, which allows them to adjust routes dynamically to avoid disruptions. Using direct transportation options and minimizing unnecessary stops in the shipping process will further protect the cargo.

4. Proper Loading and Unloading Procedures

The loading and unloading processes significantly impact operations. Correct loading practices will ensure consistent airflow within the refrigerated unit, maintaining uniform temperatures. Limiting exposure to external temperatures during loading and unloading prevents thermal shocks. Training personnel on best practices reduces the likelihood of mishandling.

5. Documentation and Communication

Accurate documentation, including shipping manifests, temperature records, and customs paperwork, ensures smooth operations. Open communication between shippers, carriers, and receivers keeps everyone aligned and ready to address issues as they arise.

Leverage Terminal49 To Track & Monitor Refrigerated Freight

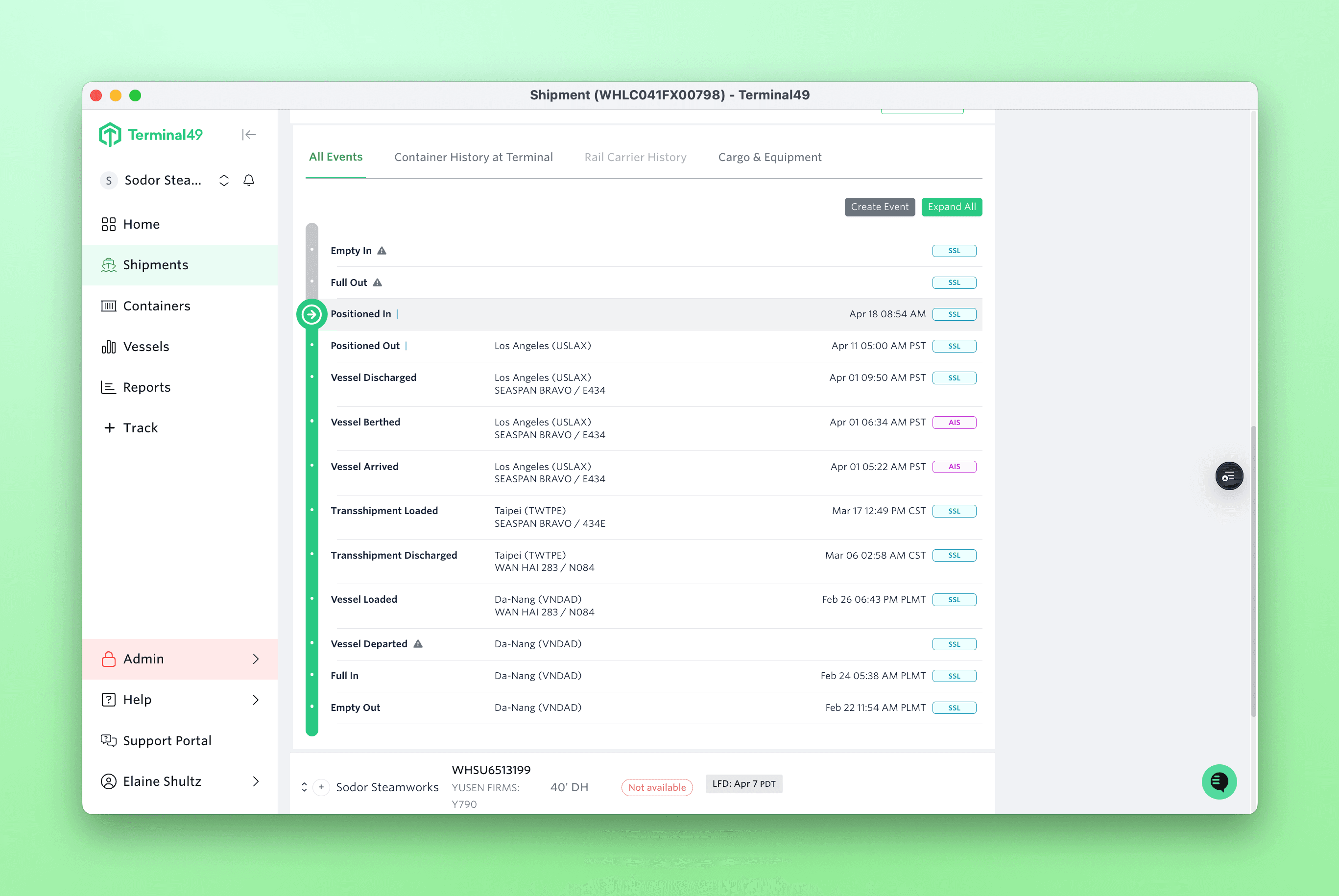

Successful refrigerated transportation or logistics in the modern era requires complete visibility. The Terminal49 platform provides real-time visibility, allowing you to monitor your shipments and every stage of the logistics process. This way, you can ensure the timely delivery of your temperature-sensitive goods. The platform enables you to monitor key shipment milestones, enhancing your ability to make informed decisions and quickly respond to any potential delays.

1. Tracking FDA Clearance

International shipping regulations are necessary, but they can be difficult to navigate. With our CBP and FDA clearance alerts, you can monitor your shipments in real-time, allowing you to effectively minimize the chance of unexpected hold-ups at the port of entry.

2. Customs Release

By monitoring customs decisions on your shipments, you can anticipate when they will be ready for the next phase of transit. This way, you can avoid bottlenecks and increase the chances of a more streamlined process, including planning and scheduling with drayage providers.

3. Vessel ETA Tracking

Shipping can be a very dynamic process but with Terminal49 you can access real-time shipment tracking, enabling you to take steps to ensure that downstream schedules remain aligned. The platform also helps logistics teams plan for unloading and delivery without unnecessary downtime.

Schedule a demo with us today.