Many of our customers rely on the Port of LA for their global trade operations. Navigating the complexities of such a massive port can be challenging, and that’s where Terminal49 steps in to help. We provide the real-time data and insights needed to manage container operations smoothly and efficiently, helping our customers avoid delays, reduce fees, and keep their supply chains moving.

The Port of Los Angeles has come a long way since its inauguration in 1907, when it was established primarily to serve Southern California's burgeoning agricultural and industrial sectors. Today, it is one of the busiest ports on the continent, handling shipments from across the globe, and is popularly referred to as ‘America's port.’

The Port of Los Angeles is approximately 20 miles south of downtown Los Angeles and is located within the San Pedro and Wilmington Los Angeles neighborhoods. Its coordinates are 33°43′48″N 118°15′45″W. Despite being built to serve a relatively small sector, the port grew significantly due to the expansion of the Panama Canal, increased trade with Asia, and its pivotal role during World War II.

Like many other ports worldwide, the introduction of containerization into shipping operations also fueled increased capacity and led to massive investments in infrastructure.

With continuous modernization and expansion, the port has established itself as a major global trade hub, handling ever-increasing cargo volumes.

Modernization and continuous expansion have ensured that the port boasts world-class facilities, including 43 miles of waterfronts that can accommodate a variety of vessels and 25 cargo terminals that handle containers, breakbulk, and automobiles.

It is also well-equipped with on-dock rail facilities that provide seamless intermodal connections and extensive warehousing and distribution networks, supporting efficient cargo storage and movement.

Port of LA Operational Information

The Ports of Los Angeles are spread over 7,500 acres (4,300 of land and 3,200 of sea), have 122 miles of on-dock rail, and operate 1,932 pieces of cargo handling equipment.

The typical cargo types handled at the ports include:

1. Containerized Cargo carrying a vast array of consumer goods, electronics, apparel, machinery, and other manufactured products.

2. Bulk cargo, including dry bulk commodities like grain, coal, and iron ore, and liquid bulk cargo, such as petroleum, chemicals, and edible oils.

3. Breakbulk Cargo such as steel, lumber, machinery, and project cargo.

4. Automobiles and other cargo, including cruise ship passengers, ferry traffic, and specialized shipments like yachts and military equipment.

In 2023, the port:

- Handled 8.6 million TEUs of containers and 157,066 automobile units.

- Handled 219 cruise calls and 1,323,313 passengers' (its busiest cruise passenger year on record).

- Received 1,712 vessels of all types

Information on the number of vessel calls, vessels at berth, vessels on anchor, last free day, yard availability percentage, etc., is updated daily and can be found on the port’s operations dashboard report.

Facilities and Services

The port of Los Angeles operates one of the highest number of terminals in the country, with internal and external warehouse operations and robust transportation options.

Here is a comprehensive list and guide to the facilities and services available at the port.

Terminals

Six major terminals operate out of the Port of Los Angeles, each with a unique approach and choice of goods.

A global terminal leader and the largest container terminal in the Western Hemisphere. APM boasts state-of-the-art infrastructure for efficient cargo handling and processes a significant portion of the port's container traffic.

- Dwell time (Avg): 3.64 days | 95th %: 6.04 days.

Everport Terminal Services

Strategically located near major Los Angeles freeways and rail lines, Everport offers seamless intermodal connectivity and efficient cargo handling.

- Dwell time (Avg): 4.44 days | 95th %: 8.35 days.

Fenix Marine Services

Known for its strategic location, innovative technologies, and sustainable practices, Fenix's modern facilities handle a variety of cargo providers.

- Dwell time (Avg): 3.92 days | 95th %: 7.54 days.

TraPac

A key player in transpacific trade, TraPac focuses on operational efficiency and customer service, utilizing advanced technology to streamline cargo handling with extensive on-dock rail facilities.

- Dwell time (Avg): 4.59 days | 95th %: 10.08 days.

Yusen Terminals

A major player in the trans-Pacific trade, Yusen offers a comprehensive range of services and specializes in handling automotive cargo.

- Dwell time (Avg): 4.18 days | 95th %: 6.70 days.

West Basin Container Terminal (WBCT)

A key gateway for U.S.-Asia trade, WBCT focuses on handling large container volumes, offering a variety of services for different cargo types and vessel sizes.

- Dwell time (Avg): 4.02 days | 95th %: 6.82 days.

Compare Dwell Times of all Port of LA Terminals

Warehouse Operations and Markets

Port of Los Angeles Operated Warehouse and Distribution Operations

- Berth 265 | Neptune Foods

- Warehouse 9 | Brouwerij West

- Berth 209 | Port of Los Angeles

- Warehouses 13, 16 & 17 | Toll Global

- Berth 264 | Tri-Marine Fish Company

- Berth 268-268A | Port of Los Angeles

- Berth 153-155A | Port of Los Angeles

- Berth 57 | AltaSea at the Port of Los Angeles

- Berths 54-55 | SSA Marine | Port of Los Angeles

- Berths 58-60 | AltaSea at the Port of Los Angeles

- Berths 179-181 | Pasha Stevedoring and Terminals

- Warehouse 10 | CRAFTED at the Port of Los Angeles

- Berth 68 | Historic Municipal Warehouse No. 1 | Port of Los Angeles

Key Warehouse Markets and Hubs

1. City of Industry

The City of Industry is a major industrial and logistics center located 20 miles east of Los Angeles.

It has a large concentration of warehouses and distribution centers. However, the market's proximity to the port and major highways like the I-10 and I-60 make it ideal for logistics and supply chain operations.

2. Vernon

Famous for its concentration of food processing and manufacturing facilities, it is located south of downtown Los Angeles.

The hub continues to see increasing warehouses catering to e-commerce and other industries.

3. Commerce

Situated between Los Angeles and the City of Industry and strategically located near major freeways, the hub provides convenient access to warehousing and logistics facilities, such as major highways and rail lines, for efficient cargo movement.

4. Carson

The hub has a bubbling industrial presence located between two major ports (Port of Los Angeles and Long Beach).

It offers shipping stakeholders a variety of warehouse and distribution center options, catering to a range of industries and businesses.

Transportation Options

The Port of Los Angeles. offers excellent connectivity to major transportation networks, enabling seamless movement of cargo across North America

1. Rail

Extensive, state-of-the-art on-dock rail facilities connect the port to major rail networks, facilitating the efficient and cost-effective transportation of containerized and bulk cargo throughout the country and beyond.

2. Road

The port is surrounded by a vast network of highways and interstates, which it leverages to provide direct access to the facility while allowing for efficient truck transportation of goods to various destinations across the country.

3. Intermodal Facilities

The port has successfully integrated several intermodal facilities, which have enabled it to ensure the seamless transfer of cargo between different modes of transportation, such as trucks, trains, and ships.

Economic Impact (Facts and Figures)

Finances

- Cargo Value $292 billion

- Adopted Budget $1.9 billion

- Operating Revenue $656 million

- Operating Expenses $299 million

- Capital Improvement Program $109 million

Top Trading Partners

- Japan $38 billion

- Taiwan $17 billion

- Vietnam $30 billion

- South Korea $18 billion

- China/Hong Kong $112 billion

Top 5 Trade Routes

- Mediterranean (2%)

- Northeast Asia (61%)

- Southeast Asia (27%)

- Northern Europe (3%)

- India Sub-continent (3%)

Infrastructure and Development

As the biggest operating port in the country, the Port of Los Angeles continues to expand and grow its capacity by developing infrastructures that allow them to handle the high volume of cargo that continues to leave and enter the country through the ports.

Some of these projects include:

1. Pier 400 On-Dock Rail Expansion

The $73 million project expanded on-dock rail capacity at Pier 400 to improve cargo flow, reduce truck traffic, and enhance air quality. The project was completed in July 2024.

2. Wilmington Waterfront Promenade

Scheduled to open in 2024, this $77.3 million project will create a community park, waterfront promenade, and public pier, improving public access to the waterfront and enhancing the surrounding community.

3. Alameda Corridor Terminus Gap Closure

Completed in June 2022, this $17.3 million project closed a gap in rail access between the port's West Basin area and the Alameda Corridor, reducing train service delays to several terminals.

4. New Marine Oil Platform

The $44.8 million project is expected to be completed in 2024. It will replace timber wharves at the Shell Oil Terminal with a new wharf and loading platform, improving efficiency and safety.

Sustainability and Environmental Protection Initiatives

The Port of Los Angeles is dedicated to sustainable growth and environmental stewardship and continues to prove it with the following programs and initiatives.

1. Clean Air Action Plan (CAAP)

The Port of Los Angeles has recently implemented a comprehensive CAAP to reduce air pollution from port-related activities while handling increasing cargo volumes.

The initiative will promote cleaner trucks, ships, cargo handling equipment, shore power, and alternative fuel investments.

2. Sustainable Aviation Fuel (SAF) Pilot Program

The port is exploring using SAF to reduce greenhouse gas emissions from air cargo operations.

3. Energy Efficiency and Renewable Energy

To reduce its carbon footprint, the port invests in energy-efficient technologies and renewable energy sources, such as solar panels and wind turbines.

4. Water Quality and Conservation

The port is committed to protecting San Pedro Bay's water quality through various programs and initiatives, including stormwater management and pollution prevention.

Regulatory and Safety Information For Ports

Ports are highly regulated, which can be challenging for shipping stakeholders, especially when they lack the requisite information.

Here is a breakdown of customs procedures, regulations, and compliance requirements:

1. Documentation and Declaration

Unless stated otherwise, the following are the necessary documentation for customs clearance purposes:

- Packing List.

- Bill of Lading (B/L)

- Certificate of Origin

- Commercial Invoice

- Import/Export License

- Customs Declaration Form

2. Tariffs and Duties

When navigating tariffs and duties, the following documentation and systems will be critical.

- Preferential Tariffs

- Payment of Duties and Taxes

- Harmonized System (H.S.) Code

3. Compliance Requirements

Compliance is not optional when shipping, and the following is expected from stakeholders:

- Regulatory Compliance: Adherence to local and international trade laws and regulations, including taxes and types of goods allowed for shipping.

- Product Standards: Compliance with health, safety, and environmental standards.

- Sanctions and Embargoes: Ensuring goods are not sourced from or destined for sanctioned countries.

4. Inspections and Audits

Shipping stakeholders can expect the following from customs and other authorities involved in the shipping process:

- Physical Inspection: Customs may physically inspect goods to verify declarations.

- Document Verification: Checking the accuracy of submitted documents.

- Post-clearance Audit: Conducted to ensure compliance after goods have been cleared.

5. Clearance Procedures

These are key details to note when clearing shipments.

- Pre-Arrival Processing: Documents must be submitted before the arrival of goods.

- Customs Brokerage: Leveraging licensed brokers to facilitate the clearance process is not compulsory but helps greatly.

- Release of Goods: Goods are released once all duties are paid and compliance is verified.

Safety Measures and Protocols for Cargo and Personnel

Shipping operations require extensive safety protocols for both cargo and the people involved in the process.

The following guidelines will be essential in navigating the shipping world.

1. Cargo Safety Measures

The following protocols will be quite vital for successful cargo handling and movement.

- Secure Packaging: Goods must be properly packed to prevent damage and tampering.

- Sealing: The use of tamper-evident seals on containers is necessary to identify fraud easily

- Temperature Control: For perishable goods, maintaining proper temperature throughout transit.

- Hazardous Materials: Compliance with regulations for safely handling and transporting hazardous materials.

- Tracking and Monitoring: GPS and RFID technology are used to monitor the location and condition of cargo.

2. Personnel Safety Protocol

Shipping operations place a high value on personnel and go to great lengths to ensure few to zero casualties during the process. That is why the following is critical:

- Training: Stakeholders must implement regular training on safety procedures, emergency response, and handling hazardous materials.

- Personal Protective Equipment (PPE): PPE, such as helmets, gloves, and safety vests, is mandatory when on-site and during the shipping process.

- Health and Safety Regulations: Stakeholders must adhere to Occupational Safety and Health Administration (OSHA) standards.

- Emergency Procedures: Stakeholders, especially carriers, ports, and terminal operators, must ensure and enforce safety protocols for fire, chemical spills, and other emergencies.

- Security Screening: Background checks and security screening for all personnel involved in handling cargo.

3. Facility Security Measures

Various facilities such as ports, terminals, warehouses, and carrier vessels follow the rules laid down to help smooth operations on these facilities.

The key rules are

- Access Control: Restricted access to cargo handling and storage areas.

- Surveillance: Installation of CCTV cameras and other surveillance equipment.

- Perimeter Security: Protect facilities using fencing, gates, and security personnel.

How to Leverage Terminal49 For Shipping Operations

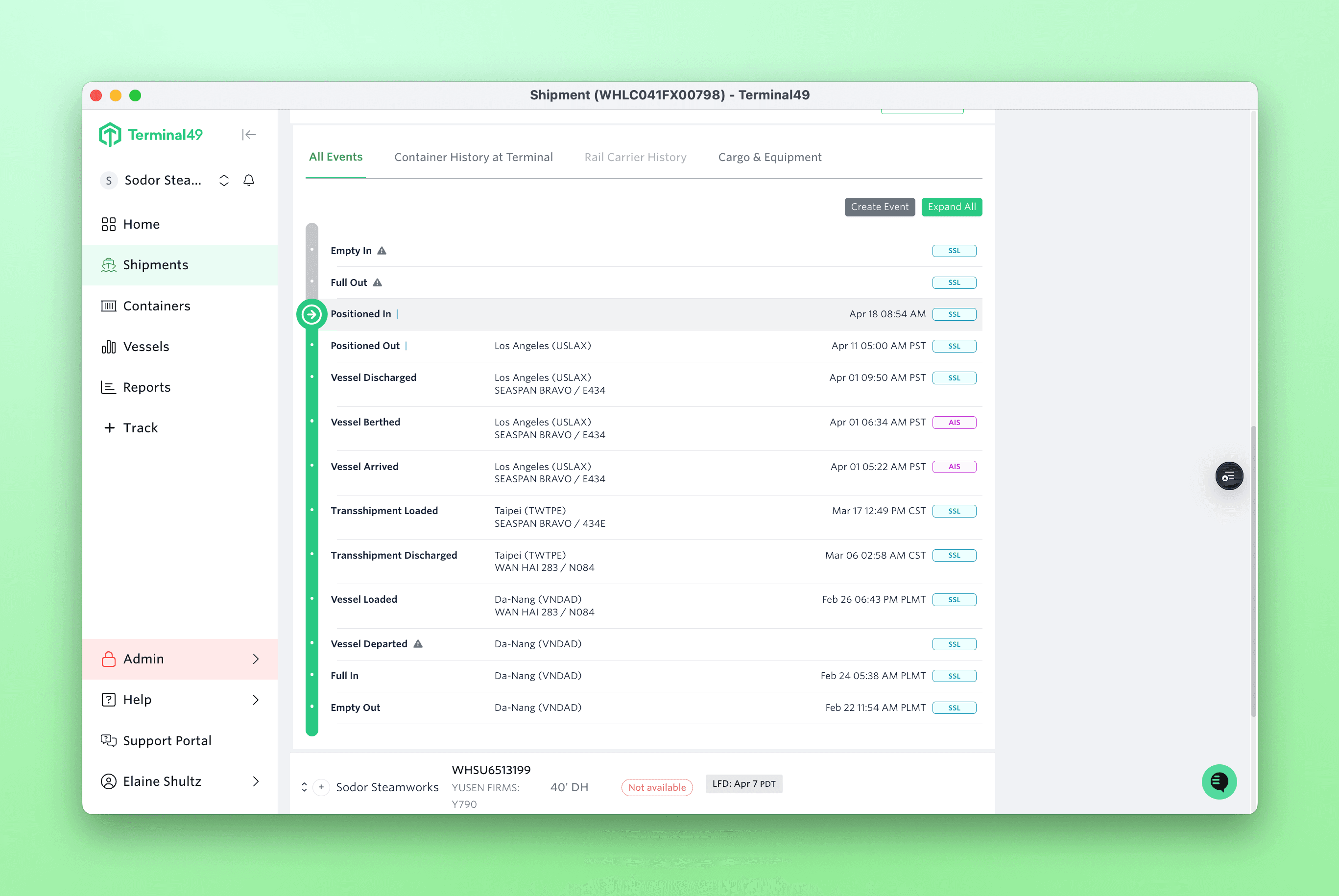

Terminal49's tracking solution plays a vital role for industry operators.

Our container tracking software can help operators improve data quality, streamline processes, and comply with new regulations. They can leverage the platform to track shipments, monitor milestones, and track their demurrage and detention fees, if any.

Terminal49's shipping solution goes well beyond compliance. Various industry stakeholders rely on it to optimize their shipping operations.

Terminal49 promises you:

- Streamlined Efficiency: Automate tedious tracking tasks, allowing your team to focus on strategic initiatives that drive growth.

- Reduced Expenses: Avoid unnecessary demurrage and detention charges by proactively managing your shipments and responding to exceptions promptly.

- Enhanced Visibility: Gain unparalleled visibility into your supply chain, enabling data-driven decisions that improve on-time delivery and customer satisfaction.

Start a free trial with us today.